- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

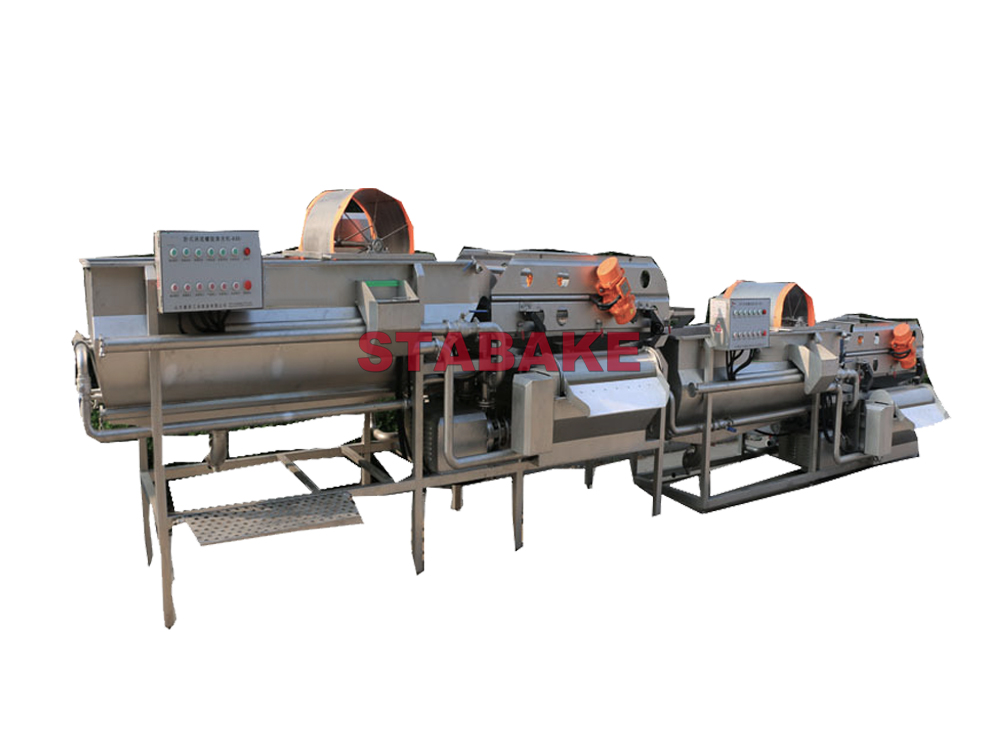

Fruit And Vegetable Cleaning Processing Line Fresh Vegetable Salad Processing Line

Description:

The fresh vegetable salad processing line include the selecting working station- cutting machine - elevator-first hydro-cyclone washing machine (can equipped with the ozone sterilizing generator,can remove the pesticide residue)-vibration draining machine - secondary washing machine (ice water cleaning can promote vegetable quality,keep vegetable taste,beneficial for the storage of the vegetable)-second vibration draining- vertical centrifugal dehydration machine.

Technical Parameter:

NO. | Equipment Name | Dimension(mm) |

1 | Six-station pick line | 2700*1020*895 |

2 | Vegetable cutter machine | 1075*705*1765 |

3 | Elevator Conveyor | 3740*602*1800 |

4 | First Hydrocyclone Washing machine | 2270*935*107 |

5 | vibration draining machine | 1305*1110*1605 |

6 | Ozone sterilization | 2270*935*1475 |

7 | Second Hydrocyclone Washing machine | 2270*935*107 |

8 | Workbin | 1150*1100*410 |

9 | Centrifugal dewater | 980*645*940 |

Potato Carrot root vegetable processing line:

NO. | Equipment Name | Picture |

1 | Pre-washing Elevator | 2170*1140*1800 |

2 | Brush washing peeling machine | 1900*818*940 |

3 | Six-station pick line | 2700*1020*895 |

4 | Elevator conveyor | 2580*1000*2064 |

5 | Vegetable dicing machine | 1370*1110*1250 |

6 | Elevator Conveyor | 3740*602*1800 |

7 | Eddy Washing machine | 2270*935*1070 |

8 | Ozone sterilization | 2270*935*1475 |

9 | Eddy Washing machine | 2270*935*1070 |

10 | Workbin | 1150*1100*410 |

11 | Centrifugal dryer | 980*645*940 |

We also can design the other vegetable processing line as you demand:

1. Fresh vegetable salad processing line: washing→ sorting→peeling and cutting→washing→sterilizing→ rinsing- Vibrating De-watering

2. Frozen vegetable processing line: pre-soak cleaning→ washing→ cutting→ blanching→ cooling→Vibrating De-watering → air drying→ freezing

3. Vegetable drying processing line: Rinsing→ Pretreatment→ washing→ cutting→ air selecting → blanching → cooling → dehydration → blending →drying.

4. Vegetable powder processing line: Rinsing→ Pretreatment→ washing→ cutting → blanching → cooling → dehydration → drying → grinding.

5. Pickled vegetable processing line: washing →water desalting→cutting→ squeezing→ mixing→packing → sterilizing→ cooling →air drying

Fruit And Vegetable Cleaning Processing Line Fresh Vegetable Salad Processing Line

Description:

The fresh vegetable salad processing line include the selecting working station- cutting machine - elevator-first hydro-cyclone washing machine (can equipped with the ozone sterilizing generator,can remove the pesticide residue)-vibration draining machine - secondary washing machine (ice water cleaning can promote vegetable quality,keep vegetable taste,beneficial for the storage of the vegetable)-second vibration draining- vertical centrifugal dehydration machine.

Technical Parameter:

NO. | Equipment Name | Dimension(mm) |

1 | Six-station pick line | 2700*1020*895 |

2 | Vegetable cutter machine | 1075*705*1765 |

3 | Elevator Conveyor | 3740*602*1800 |

4 | First Hydrocyclone Washing machine | 2270*935*107 |

5 | vibration draining machine | 1305*1110*1605 |

6 | Ozone sterilization | 2270*935*1475 |

7 | Second Hydrocyclone Washing machine | 2270*935*107 |

8 | Workbin | 1150*1100*410 |

9 | Centrifugal dewater | 980*645*940 |

Potato Carrot root vegetable processing line:

NO. | Equipment Name | Picture |

1 | Pre-washing Elevator | 2170*1140*1800 |

2 | Brush washing peeling machine | 1900*818*940 |

3 | Six-station pick line | 2700*1020*895 |

4 | Elevator conveyor | 2580*1000*2064 |

5 | Vegetable dicing machine | 1370*1110*1250 |

6 | Elevator Conveyor | 3740*602*1800 |

7 | Eddy Washing machine | 2270*935*1070 |

8 | Ozone sterilization | 2270*935*1475 |

9 | Eddy Washing machine | 2270*935*1070 |

10 | Workbin | 1150*1100*410 |

11 | Centrifugal dryer | 980*645*940 |

We also can design the other vegetable processing line as you demand:

1. Fresh vegetable salad processing line: washing→ sorting→peeling and cutting→washing→sterilizing→ rinsing- Vibrating De-watering

2. Frozen vegetable processing line: pre-soak cleaning→ washing→ cutting→ blanching→ cooling→Vibrating De-watering → air drying→ freezing

3. Vegetable drying processing line: Rinsing→ Pretreatment→ washing→ cutting→ air selecting → blanching → cooling → dehydration → blending →drying.

4. Vegetable powder processing line: Rinsing→ Pretreatment→ washing→ cutting → blanching → cooling → dehydration → drying → grinding.

5. Pickled vegetable processing line: washing →water desalting→cutting→ squeezing→ mixing→packing → sterilizing→ cooling →air drying

Whatsapp/ Wechat: 0086-18560205581

Whatsapp/ Wechat: 0086-18560205581